RECHERCHE

FONDATION CARLOS SIMON Recherche sur la santé des femmes

Paterna. Valencia. Espagne

Nous réalisons les projets de laboratoire les plus sûrs et les plus efficients au monde dans lesquels les chercheurs prennent plaisir à améliorer la société.

Chez Burdinola, nous réalisons des études pour des développements et des installations de laboratoire complexes en tenant compte des réglementations, des flux de travail, des processus et des équipements d’une manière conjointe et intégrée.

En savoir plus

Tout ce dont vous avez besoin pour rendre votre laboratoire sûr et efficient.

Maintenez votre laboratoire à jour dans les meilleures conditions de sécurité.

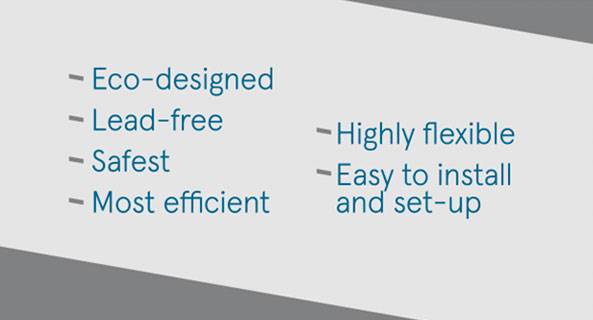

Notre nouvelle gamme de sorbonnes s'impose comme la meilleure option en termes de sécurité et d'efficacité énergétique.

Découvrez la nouvelle gamme eFlex

Notre expérience de plus de 40 ans dans la conception de laboratoires, nous définissent comme une marque internationale de premier plan. Aller à Burdinola Worldwide

RECHERCHE

Paterna. Valencia. Espagne

PHARMACEUTIQUE ET COSMÉTIQUE

Derio. Espagne

ÉDUCATION

Abu Dhabi. Émirats arabes unis